Get started with Dynamics 365 Supply Chain Management Full Cycle

Introduction

Dynamics 365 Supply Chain Management provides a single source of business intelligence that drives productivity from assets and resources, aligns employees toward strategic goals, and enables real-time response to organizational and customer demands.

This module introduces the distribution and trade features of Supply Chain Management and their related modules. Additionally, it explains how this functionality helps businesses accelerate the speed and accuracy of their operations with streamlined processes that effectively coordinate people, assets, and resources to reduce costs, improve service levels, and drive growth.

In this module, you will:

- Learn the benefits of distribution and trade in Supply Chain Management.

- Get an overview of distribution and trade features in Supply Chain Management.

If you want to learn more about other Dynamics 365 apps, we recommend the Microsoft Dynamics 365 Fundamentals learning path, where you can also learn about cloud concepts, and Microsoft Power Platform.

Next unit: Benefits of Supply Chain Management

Supply Chain Management enables organizations to run smarter with connected operations and to perform the following tasks:

Create an ideal manufacturing mix from discrete, lean, and process in a single, unified solution to support processes across the supply chain.

Optimize manufacturing parameters for each product family, including make to stock, make to order, pull to order, configure to order, and engineer to order.

Streamline scheduling with real-time visibility into resources by using a unified resource model and scheduling engine by using the Financial management module in Supply Chain Management.

Optimize the flow of manufacturing material and finished goods with advanced warehouse and logistics management.

Improve product quality by identifying and resolving issues through real-time insights and predictive intelligence.

Automate and streamline your supply chain

Supply Chain Management helps organizations optimize fulfillment and reduce costs by synchronizing logistics across sites, warehouses, and transportation modes. Additionally, it enables organizations to provide faster response to customer demand by automating a seamless coordination of an order-to-cash processes.

Throughout the operations, Supply Chain Management provides visibility and control across all sites and warehouses for proactive response to issues by using financial analysis capabilities.

By unifying processes from sales to fulfillment, Supply Chain Management seamlessly connects sales and purchasing with logistics, production, and warehouse management for a 360-degree view of an organization’s supply chain. It reduces procurement costs and gains greater control by automating procure-to-pay processes.

AI-Powered user assistance

Copilot offers in-product, AI-based contextual help, allowing you to ask natural language questions about tasks, configurations, and concepts, such as sending sales orders to the warehouse or setting up lead-time management. This generative AI-based assistance, available in multiple languages and regions, will enhance your user experience by providing immediate, role-specific support and accelerating learning.

Next unit: Overview of Supply Chain Management

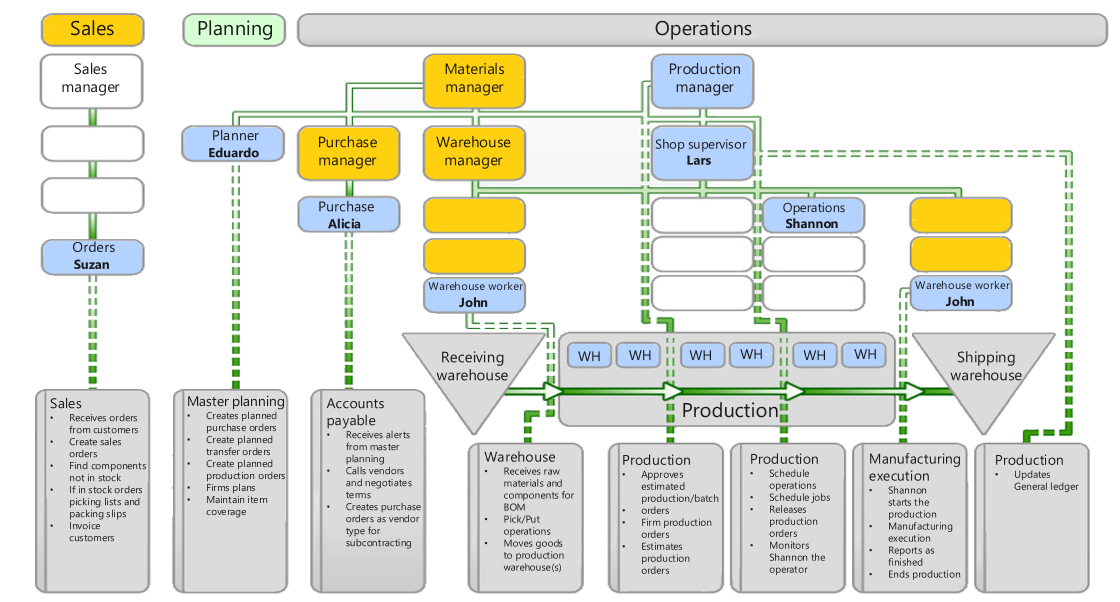

Distribution and trade in Supply Chain Management is organized into various modules and role-based workspaces that focus on daily tasks that are related to the assigned role.

Role-based security in Supply Chain Management and Dynamics 365 Finance helps keep financial and operational data secure.

Below are the responsibilities of operational leaders.

Increase operational efficiency - Trying to accelerate the speed and accuracy of the business operations with streamlined processes that effectively coordinate people, assets, and resources to reduce costs, improve service levels, and drive growth.

In Finance, the Fixed assets module controls the assets in the supply chain by integrating with the Inventory management module in Supply Chain Management.

The Human resources module in Finance, and Organization administration modules control resources such as people, machines, and vendors.

Improve strategic planning – The Master planning and Inventory management modules assist companies in improving strategic planning by providing a unified view of inventory, warehouse, manufacturing, service, and logistics with predictive analytics that turn data into insights to support better strategic decisions.

Optimize workforce productivity - Providing a single source of business intelligence that drives productivity from assets and resources, aligns employees toward strategic goals, and enables real-time response to organizational and customer demands.

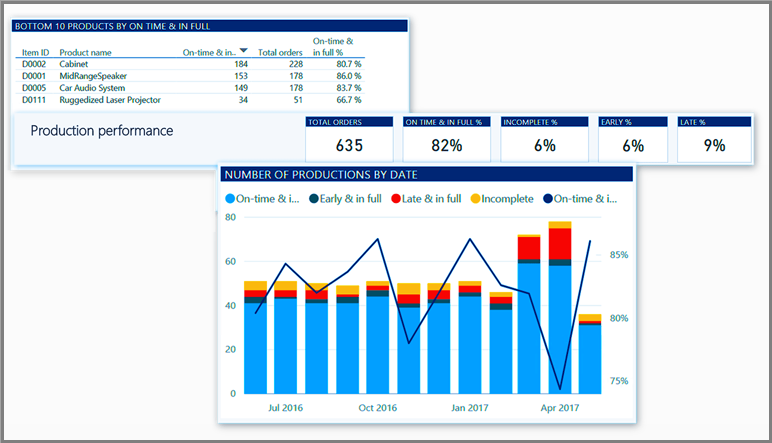

Supply Chain Management offers tools and features with built-in intelligent controls such as charts, Key Performance Indicators (KPIs), and workspaces to optimize workforce productivity.

All incoming and outgoing funds will be recorded in the General ledger in Finance, and each bank has a corresponding account in the chart of accounts. This eases the reconciliation of bank statements with financial management transactions in periodic processing.

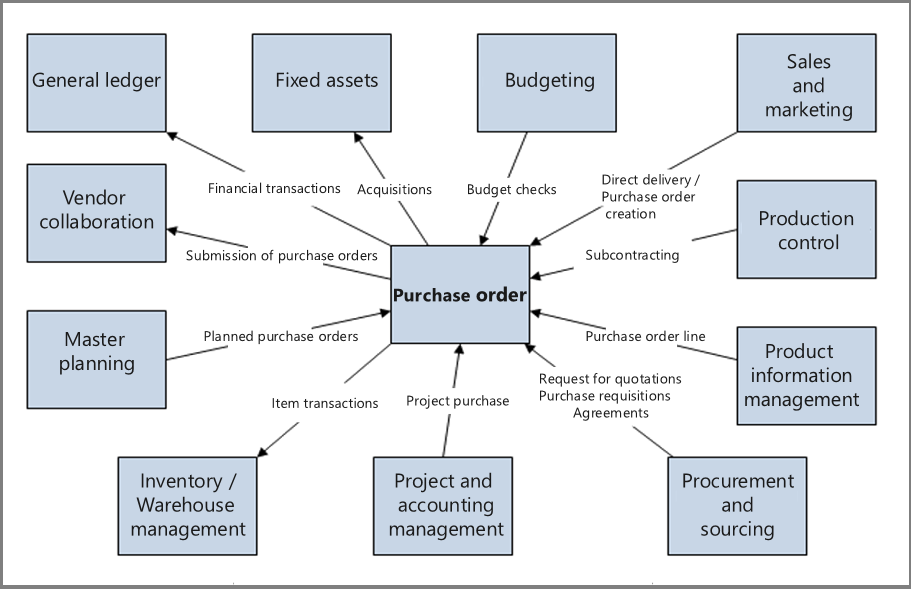

By using the Procurement and sourcing module in Supply Chain Management, you can perform all purchases, negotiate and create purchase agreements that are specific to a vendor, manage purchase orders with or without change management, approve workflow, and more. Your material managers can also make use of the supply risk assessment dashboard to understand the velocity of supply chain risks as well as the business impact of potential disruptions to your procurement cycle.

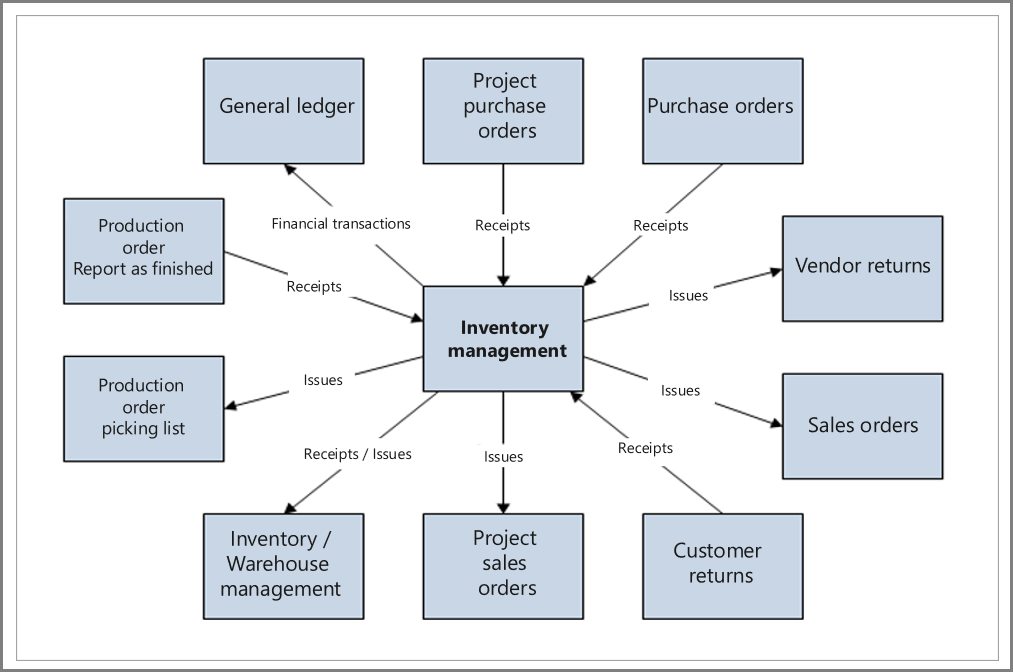

You can control the items in a warehouse location and handle their movement in the supply chain. Operations such as counting, transfer, quarantine, and quality controls are easily managed by using the Inventory management and Warehouse management modules.

All sales orders, negotiating and creating sales agreements that are specific to a customer, and managing return orders are performed by using the Sales and marketing module.

The Transportation management module can help you to find routes for delivering goods to your customers by using software to calculate costs and identify the best route based on the cost or time of delivery.

The next units take a closer look at each of these modules.

Next unit: Cost accounting

Cost accounting lets you collect data from various sources, such as the general ledger, sub-ledgers, budgets, and statistical information. You can then analyze, summarize, and evaluate cost data so that management can make the best possible decisions for price updates, budgets, cost control, and so on.

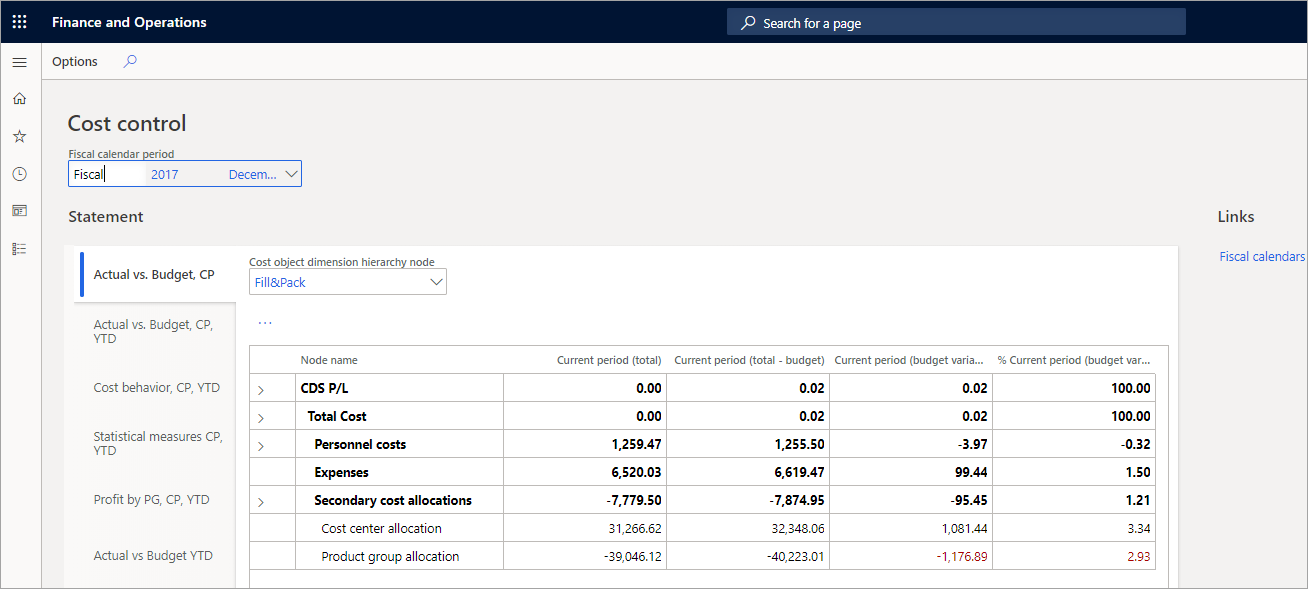

The Cost control workspace is a central point where managers who are responsible for controlling a cost object or a set of cost objects within a dimension or across dimensions (for example, cost centers and product groups) can access reports. The reports in the workspace are fully managed by cost accountants so that the layout and data that are used for reporting can be consistent across the whole organization.

This image shows the Cost control page in Cost accounting > Workspaces > Cost control

For more information, see the Get started with cost accounting for supply chains in Dynamics 365 Finance learning path.

Cost management in Supply Chain Management lets you work with the valuation and accounting of raw materials, semi-finished goods, finished goods, and work-in-progress assets. It is the process of defining, managing, and reporting inventory accounting and manufacturing accounting.

You can define cost policies in the following areas:

- Predetermined cost

- Inventory accounting

- Manufacturing accounting

- Indirect cost accounting

- Ledger integration

For example, you can define which inventory valuation methods, such as (FIFO (First in, First out), (LIFO (Last in, First out), (LIFO date (Last in, First out Date), Weighted average, standard cost, or moving average that you want to apply to products in the item model group in inventory accounting.

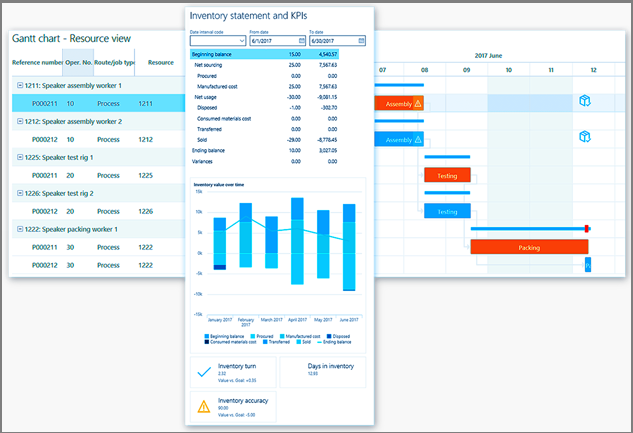

You can access inventory accounting and manufacturing accounting from the Cost administration and Cost analysis workspaces. These workspaces provide a comprehensive overview of the current status, KPIs, and detection of deviation.

Manufacturing accounting lets you handle job order costing in production orders and batch orders, in addition to backflush costing in lean manufacturing.

The cost management Power BI content provides managerial insight into inventory and work-in-progress (WIP) inventory and how cost flows through them by category over time. The information can also be used as a detailed supplement to the financial statement.

Next unit: Inventory management and Warehouse management

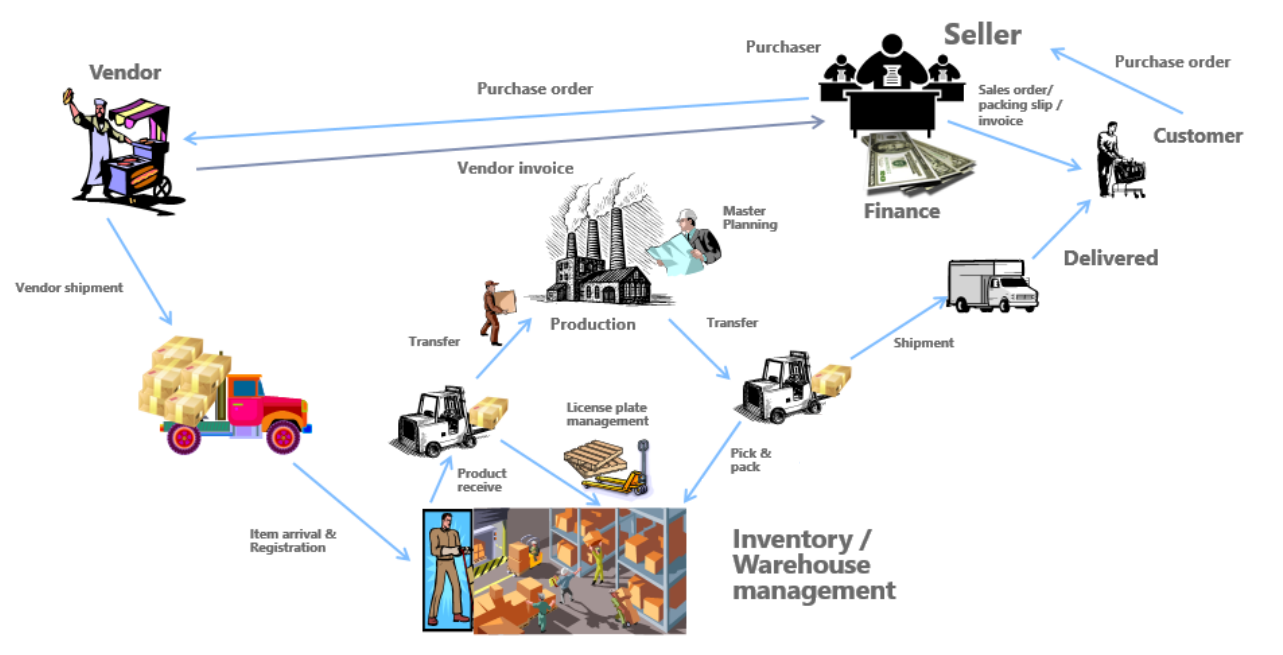

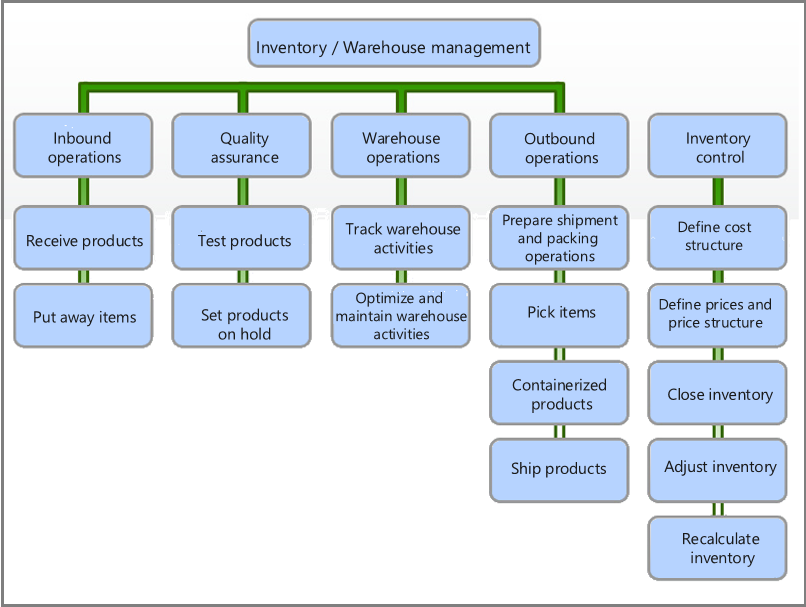

The following image illustrates the typical processes of an organization by using the Inventory management and Warehouse management modules in Supply Chain Management.

You can use the Inventory management and Warehouse management modules to perform the following tasks:

- Inbound operations

- Quality assurance

- Warehouse operations

- Outbound operations

- Inventory control

For more information about the Inventory management and Warehouse management modules, see the following modules and learning paths.

Configure and work with inventory management in Dynamics 365 Supply Chain Management

Configure and work with warehouse management in Dynamics 365 Supply Chain Management

Next unit: Master planning

Master planning allows companies to determine and balance the future need for raw materials and capacity to meet company goals.

Master planning assesses the following:

- Raw materials and capacities that are currently available.

- Raw materials and capacities that are required to complete production. For example, determining what must be manufactured, purchased, transferred, or set aside as safety stock before you can complete production.

Master planning uses the above information to calculate the requirements and generate planned orders such as purchase, transfer, and production orders.

The following image illustrates the integration of the Master planning module in Supply Chain Management with other modules in Finance.

The three main planning processes are:

- Master planning - The Master plan calculates net requirements. It is based on actual current orders and enables companies to control inventory replenishment on a short-term, day-to-day basis. Another term to describe it is the Net requirements plan.

- Forecast planning - The Forecast schedule calculates gross requirements. It is based on future projections (or forecasts), and enables companies to conduct long-term planning of materials and capacity.

- Intercompany master planning - The Intercompany master plan calculates net requirements across legal entities. It connects demand and supply between companies not only for short term, firm demand, and supply, but also for long-term, planned (that is not yet firmed) demand and supply.

For more information about master planning, see the Configure and use master planning in Dynamics 365 Supply Chain Management module.

Next unit: Procurement and sourcing

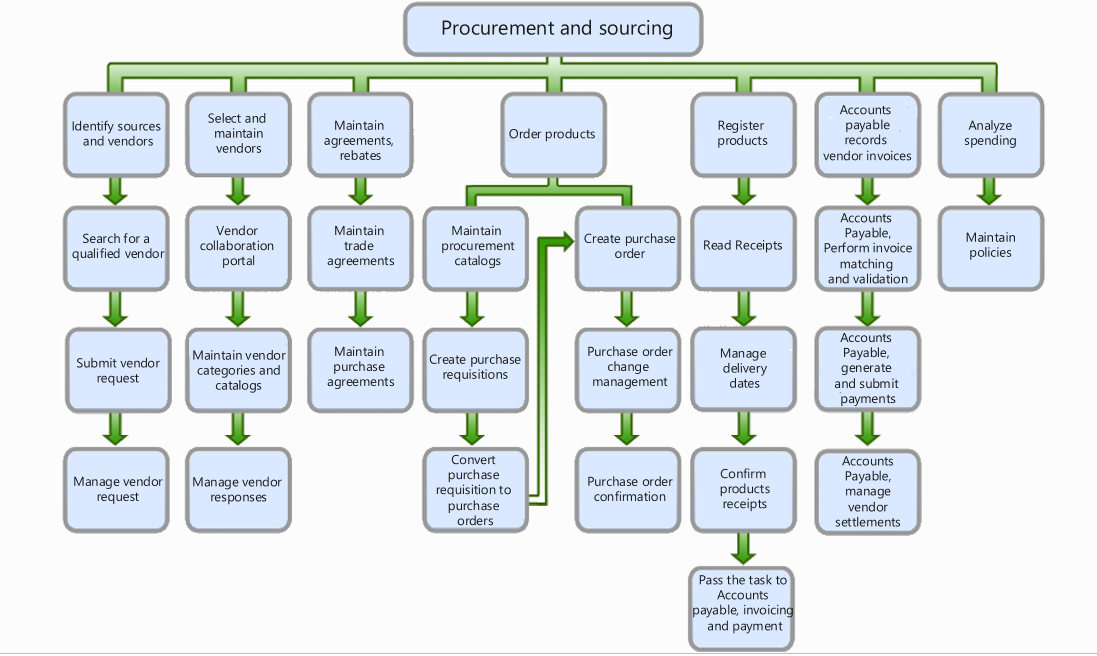

Procurement and sourcing covers all the steps from identifying a need for product and services through procuring the product, receiving, invoicing, and processing the payment with vendors. Procurement processes can be configured for specific business needs by defining purchasing policies and workflows.

The following image illustrates typical business processes that use the Procurement and sourcing module in Supply Chain Management.

For more information, see the Configure and manage procurement and vendors in Dynamics 365 Supply Chain Management learning path.

Next unit: Vendor collaboration

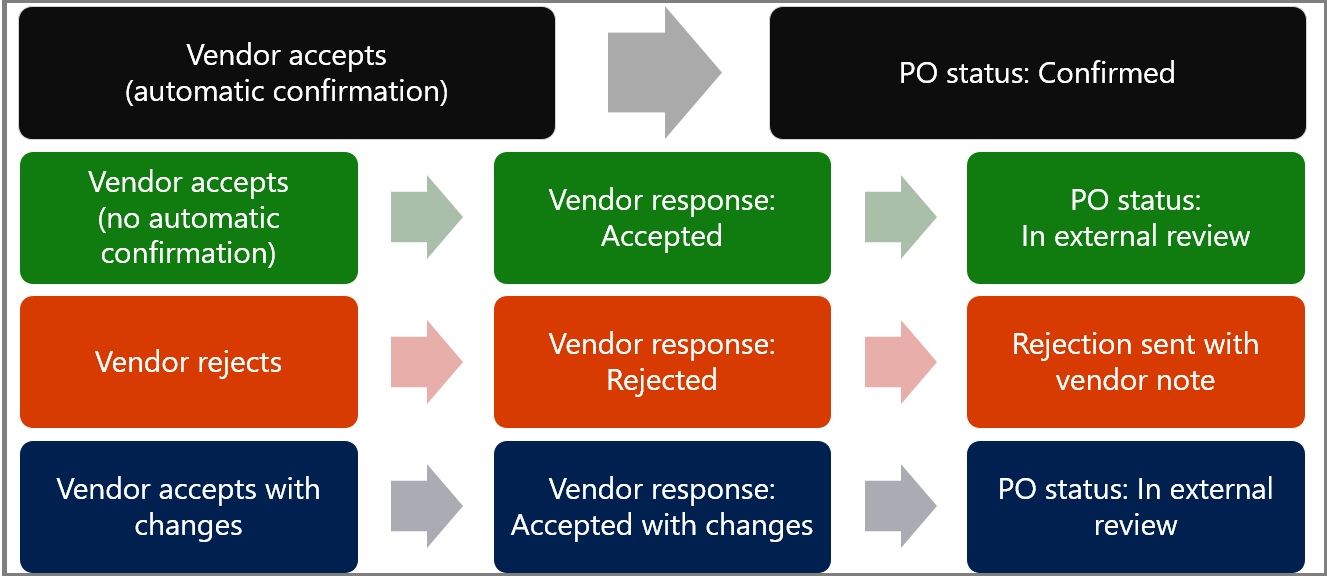

The Vendor collaboration interface in Supply Chain Management exposes a limited set of information about purchase orders, invoices, and consignment stock to external vendor users. From this interface, a vendor can also reply to requests for quotation (RFQs), and view and edit basic company information.

The following image illustrates typical processes between a company and a vendor that would use the Vendor collaboration features in Supply Chain Management.

For more information, see the Configure and manage vendor collaboration in Dynamics 365 Supply Chain Management module.

Next unit: Sales and marketing

Within the Sales and marketing module, users can store and use data related to their relationships with leads, opportunities, customers, and prospects. You can use marketing campaigns and activities to develop those relationships and use the sales functionality to create quotations, sales orders, and sales invoices.

Sales quotations enable your business to create a non-binding document with the items or services that a prospect or customer wants to buy from you. You can add any other charges or discounts to the quotation, and see a breakdown of any other information that may be required before creating a sales order. When the customer or prospect approves the quote, it is confirmed, and the system generates a sales order. You must create a customer account for a prospect prior to confirming the quotation.

A sales agreement is a contract between your business and a customer to purchase a product in a specific quantity over a specified period, in exchange for special pricing or discounts. These discounts or special prices are systematically applied when creating a sales order. The sales order is considered a binding agreement between you and a customer to buy your company's item(s) or service(s).

The sales order type must be specified when creating a sales order. The sales order types are:

| Sales order type | Description |

|---|---|

| Journal | Use this type as a draft for a sales order. This type does not affect the stock quantities and doesn't generate item transactions. |

| Subscription | Use this type for recurring orders. When the order is invoiced, the order status is automatically set to an open order. The delivered quantity that was invoiced and the remaining deliveries are updated. You can't use this sales order type if you're using the Warehouse management functionality. |

| Sales order | Use this type when a customer has placed or confirmed an order. |

| Returned order | Use this type when a customer returns an item. A return-item number (RMA number) is automatically assigned. |

| Item requirements | This type is created automatically when you make an item sale through a project. |

The sales process involves three types of invoices:

- Customer invoice - A bill to the customer for a purchase. These are created based on sales orders and complete the process once the order is packed.

- Free text invoice – This invoice is not related to a sales order but contains order lines that include ledger accounts, a description, and a sales amount, but not an item number.

- Proforma invoice - This is a draft invoice that is generated prior to the invoice posting.

For more information about the Sales and Marketing module, see Sales and marketing overview.

Next unit: Customer portal

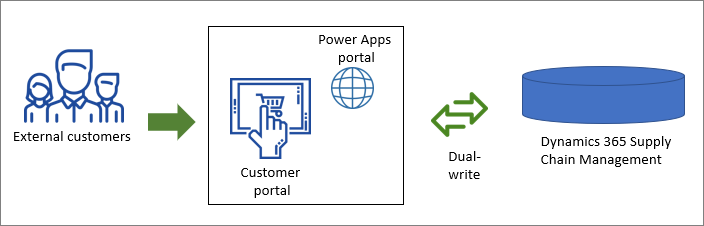

Supply chain systems rely on integration. They require that inventory, customer demand, and sales departments are integrated instead of residing in separate silos. The Customer portal helps organizations that use Supply Chain Management enhance this integration and more effectively keep their customers informed.

The Customer portal is a Power Pages template that allows businesses to create an externally facing website for customers to access that is connected to your Supply Chain Management environment.

The template uses dual-write, Supply Chain Management, and Power Pages that require little to no coding to make portals. The template can be modified to represent the company's brand, add increased functionality, and change the user experience.

Out of the box functionality of the Customer portal template includes:

- View order history

- View account information

- Create orders

- Preconfigured web roles and entity permissions for Power Pages users

- Invitation capabilities to invite customers to the portal.

The functionality that the Customer portal template offers can be modified as desired.

The Customer portal depends on Power Pages and dual-write.

- Power Pages - To host the Customer portal; portals are licensed based on usage.

- Dual-write – To enable dual-write for Supply Chain Management entities

To learn more about how to set up and manage the Customer portal see Install, set up, and update the Customer portal.

Next unit: Product information management

Product information is the backbone of supply chain and retail applications across all industries. It refers to processes and technologies that focus on centrally managing information about products (for example, across supply chains).

It's important that shared product definitions, documentation, attributes, and identifiers be used. In the various modules of a business solution, product-specific information and configuration are required to manage the business processes that are related to specific products, product families, or product categories.

A product is primarily defined by a product number, name, and description.

However, other data is also required to describe a product or service:

- Product type Item or service

- Product subtype Distinct products or product masters

- Definition of the product variant model:

- Product dimensions and dimension groups

- Product nomenclature

- Product configuration models

- Association of the product with one or more categories

- Definition of the product and category attributes

- Product images

- Attachments

- Units of measure and related conversions

- Translations for all names and descriptions

Enhanced Product Insights with Copilot

You can access a Copilot-powered, context-aware product summary by simply hovering over a product number. This tailored feature provides a quick overview of key information related to a selected product, incorporating data from other pages you frequently use based on your role. Copilot intelligently filters and highlights essential product details, minimizing irrelevant data and ensuring that each summary is relevant to your work context. By prioritizing critical attributes and dimensions, this tool is designed to enhance decision-making and streamline your workflow in Supply Chain Management to be more relevant and focused.

For more information, see the Create products and product masters in Dynamics 365 Supply Chain Management module.

Next unit: Production control

The production of products, a process that is also known as the production life cycle, follows specific steps that are required to complete the manufacturing of an item. The life cycle begins with the creation of the production order, batch order, or kanban. It ends with a finished, manufactured item that is ready for either a customer or another phase of production. Each step in the life cycle requires different kinds of information to complete the process. As each step is completed, the production order, batch order, or kanban shows a change in the production status.

Different types of products require different manufacturing processes.

The Production control module is linked to other modules, such as Product information management, Inventory management, General ledger, Warehouse management, Project accounting, and Organization administration. This integration supports the information flow that is required to complete the manufacturing of a finished item.

The production process is typically influenced by the cost accounting and inventory valuation methods that are chosen for a specific production process. Supply Chain Management supports both actual cost (first in, first out (FIFO); last in, first out (LIFO); moving average; and periodic weighted average) and standard cost methods. Lean manufacturing is implemented based on the backflush costing principle.

The choice of the cost measurement methods also defines the requirements for reporting about material and resource consumption during the production process. Typically, actual cost methods require accurate reporting on the job level, whereas periodic costing methods allow for less granular reporting of material and resource consumption.

For more information, see the Get started with production control in Dynamics 365 Supply Chain Management module.

Next unit: Intercompany trade

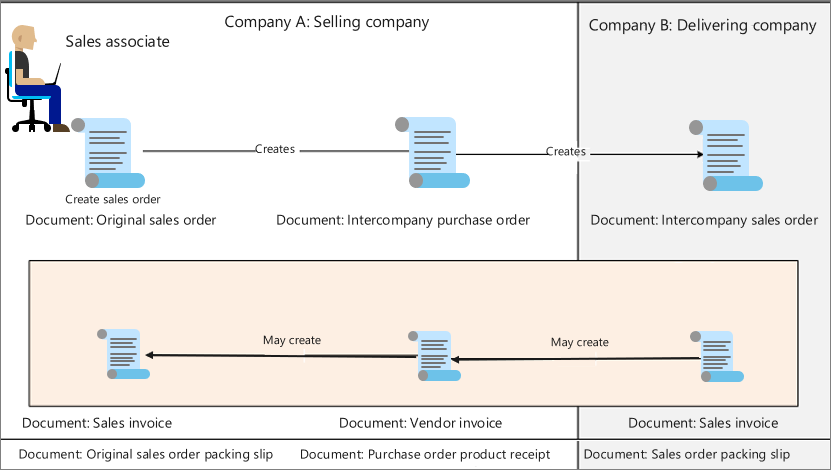

Large organizations often buy and sell among their subsidiaries. Supply Chain Management facilitates intercompany trade so that an organization's legal entities can trade goods while all documents are automatically generated for the participating legal entities, thus saving the organization time and money.

The following image illustrates the typical intercompany trade processes of a business that Supply Chain Management supports, and how transactions flow between the selling company and the delivering company for non-direct delivery scenarios.

Non-direct delivery - Goods are physically received and then shipped from the selling company to a customer.

Direct delivery - Goods are not physically received in the selling company. The goods are sent directly to the customer from the delivering company, on request from the selling company.

For more information, see the Configure and use intercompany trade in Dynamics 365 Supply Chain Management module.

Next unit: Warehouse management

The Warehouse management module in Supply Chain Management lets you manage warehouse processes in manufacturing, distribution, and retail companies. This module has a wide range of features to support the warehouse facility at an optimal level, at any time and includes full support for fully implementing a mobile device with user-friendly, no programming, functionality.

Warehouse management is fully integrated with other business processes in Supply Chain Management such as transportation, manufacturing, quality control, purchase, transfer, sales, and returns.

For more information, see the Configure and work with warehouse management in Dynamics 365 Supply Chain Management learning path.

Next unit: Transportation management

The Transportation management module in Supply Chain Management lets you use your company’s transportation, and allows you to identify vendor and routing solutions for inbound and outbound orders.

For example, you can identify the fastest route or the least expensive rate for a shipment.

You can use transportation management in Supply Chain Management for the following scenarios.

- When you are using external logistics providers for transportation activities.

- The company's own fleet is available for delivery/pickup, and delivery charges are transferred to customers.

- The company's own fleet is available for delivery/pickup, but delivery charges aren't transferred to customers because product prices include transportation.

- Logistics service is provided by another legal entity in the same company.

For more information, see the Configure and work with transportation management in Dynamics 365 Supply Chain Management learning path.

Next unit: Lab - Explore Dynamics 365 Supply Chain Management

- Ensure that you're signed in to Microsoft Learn.

- Select Launch VM mode or Sign in to launch VM mode in this unit.

- In the Resources tab on the lab side bar, select the T icon next to Password in the WIN22FO10041 (Prod) box below the Resource Group heading, to have the administrator password for the Virtual Machine (VM) entered for you.

- Select Enter.

- Select No in the Networks page.

- Microsoft Edge opens. Wait for it to navigate to the Sign in page for finance and operations. If you experience an issue with the Sign in page loading, try to restart the browser in the VM.

- On the Microsoft Sign in page in finance and operations, place your mouse cursor into the Username field.

- On the Resources tab of the lab side bar, below the Azure portal heading, select the T icon next to Username, then press Enter.

- Your mouse cursor is now in the Password page.

- On the Resources tab of the lab side bar, below the Azure portal heading, select the TAP field to select TAP token, then press Enter.

- In the Save password window, select Never.

- Select Accept in the Permissions requested page.

- To see the lab instructions, select the Instructions tab on the lab side bar.

You can now begin your work on this lab.

Scenario

Now that you've learned about the basics of Dynamics 365 Supply Chain Management, and the modules and features that it includes, it’s your turn to explore.

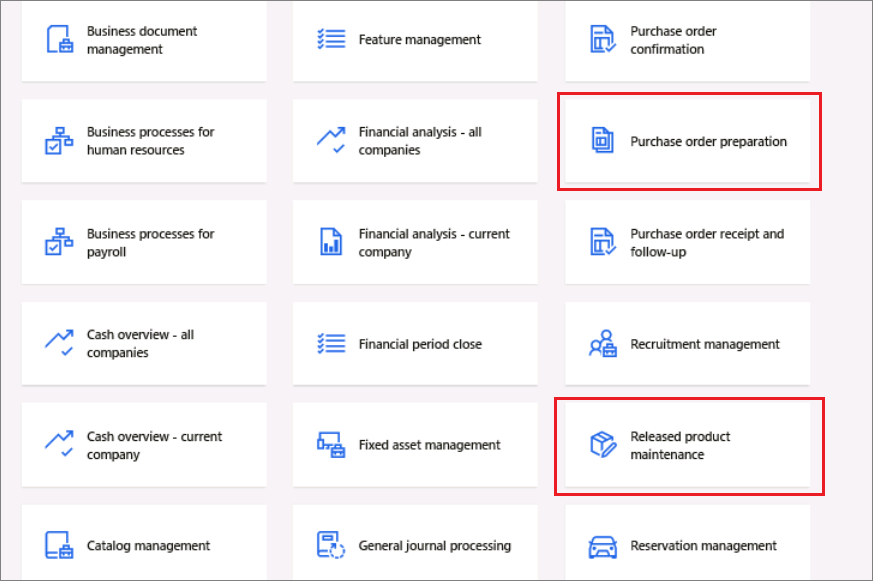

After you've logged in to the lab environment, by following the instructions above, you can select tiles on the Home page to open workspaces. For example, Purchase order preparation, or Released product maintenance.

You close a workspace by selecting the X in the top right.

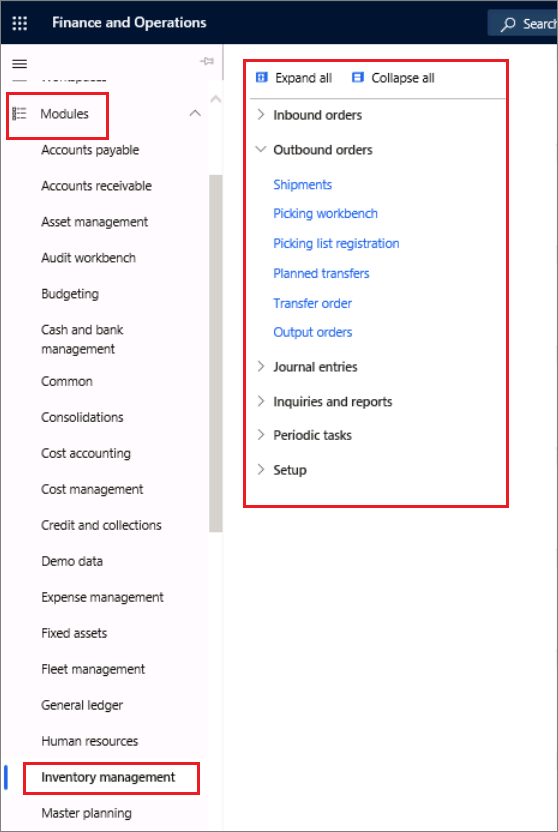

Select the Modules icon in the navigation pane on the left, and open a module, and explore the many pages in that module. For example, Inventory management.

Note

In this lab environment, there are more Dynamics 365 apps installed than Dynamics 365 Supply Chain Management. Therefore, you will also see modules that are not part of Supply Chain Management.

When have finished exploring Dynamics 365 Supply Chain Management, you can close the lab environment.

Close the lab environment

- Select Done in the Instructions pane in the lab side bar.

- In the Lab is complete window, select Continue, and then select Leave to return to the next unit in the module.

Comments

Post a Comment