3 Ways to Manage Retail Replenishment in Microsoft Dynamics AX 2012 R3

3 Ways to Manage Retail Replenishment in Microsoft Dynamics AX 2012 R3

Retailers often struggle with the complexities of automating the fulfillment of the future need of customers. In this article, we will focus on how Microsoft Dynamics AX 2012 helps retailers to adopt different replenishment techniques to acquire products and support anticipated need. (Please note, we will not be talking about how to get to that future need because this is where Demand Forecasting in Microsoft Dynamics AX 2012 R3 comes into play.)

In Microsoft Dynamics AX 2012 R3, inventory for a store can be replenished via cross docking, buyer's push or normal purchase order processing. Cross docking is a warehouse management process where shipments arrive at the inbound dock, get unloaded, and then get taken to the outbound dock to deliver out. This avoids storage and the associated cost. Buyer's push is used where a centralized purchasing department gets the shipments and then the inventory is distributed (pushed) to individual warehouses or stores. The major different between cross docking and buyer's push is that cross docking works with the purchasing quantity that comes from the originated purchase order, however buyer's push works with the available or on hand quantity of product(s). Let us take a look at each process and how it works in Microsoft Dynamics AX 2012 R3.

First we need to create a Replenishment Hierarchy for stores. Go to:

Organization administration>Setup>Organization>Organization hierarchies.

Create a new hierarchy and assign "Retail replenishment" purpose to it.

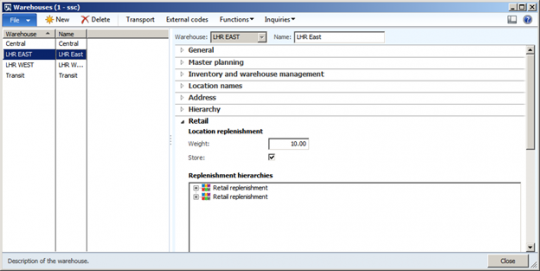

Next, specify a default weight for the warehouse that is associated with the store. We can do this on the Retail tab:

Inventory management>Setup>Inventory breakdown>Warehouses form>Retail tab.

This is not really the default product weight. It's just a weight figure for calculating the replenishment quantity and we will see its usage later in this article.

Whether we are using cross docking or buyer's push, there are three inventory distribution methods: Replenishment rules, Location weight and Fixed quantity for all.

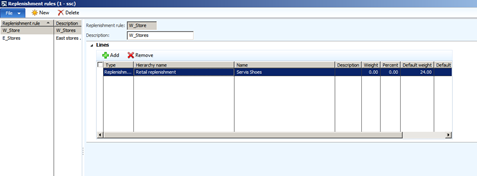

Replenishment Rules

Using this distribution method, we can create rules to override the default weight (on a warehouse) for a retail replenishment hierarchy or individual stores in a hierarchy. In the earlier step, we have already created the replenishment hierarchy. Selecting a replenishment hierarchy on a rule will bring the total weight for all stores (from associated warehouses) in the hierarchy as shown below:

However, for this article, we will use an individual store on the rule.

Cross Docking

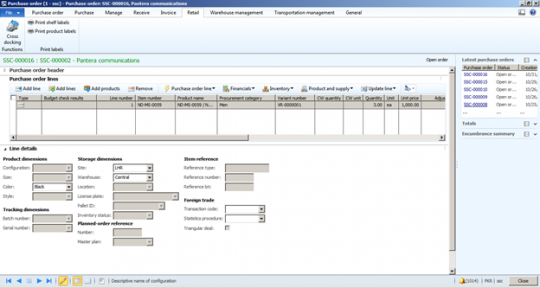

Now let's create a purchase order and select a warehouse other than docking warehouse on the PO line.

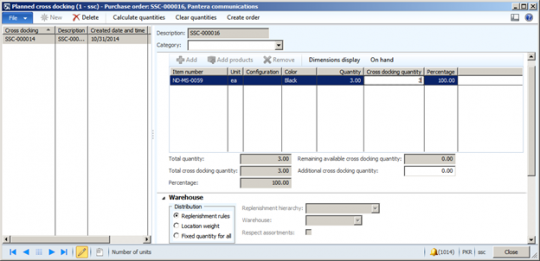

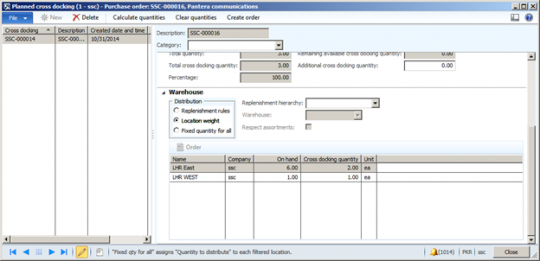

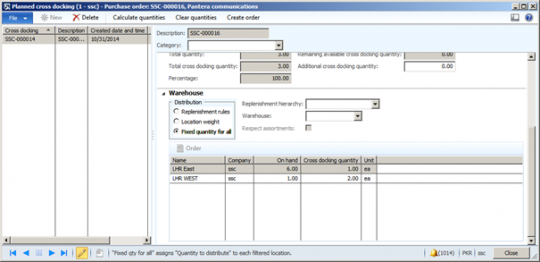

On the Retail action pane tab, click the Cross docking button in the Functions action pane group. The Planned cross docking form will be opened.

You can either enter the full quantity of 3 or less than that since only 3 are available on the PO line.

Replenishment rules

On the Warehouse fasttab, select Replenishment rules as the Distribution method and then click the Calculate quantities button in the action pane strip of the form.

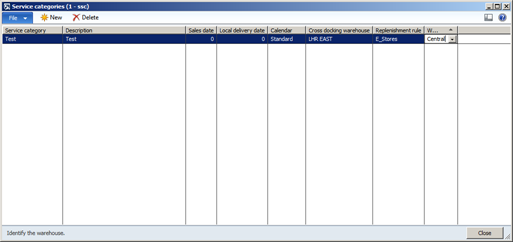

The application first checks if the service category associated with the PO has a replenishment rule specified in:

Retail>Setup>Replenishment>Service categories form

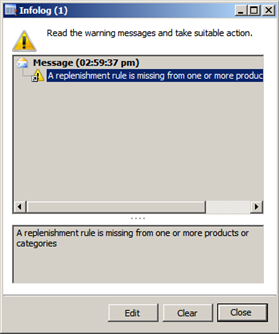

If it is, the rule is picked from the service category record. Please note that the service category is associated with the vendor master for which the PO is created (Vendor details form>Retail fasttab). If the replenishment rule is not found on the service category, the application then looks for the rule specified on the retail category of the PO line product in the Retail product hierarchy. If the rule is also not specified on the Retail category, we will get the following warning message:

In our case, we have already specified the rule on the Service category level.

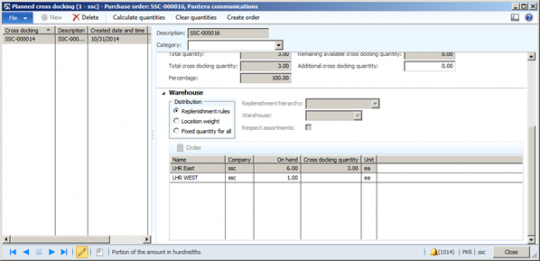

Now after calculating the quantities on the Planned cross docking form, the quantity on the PO line has been distributed as shown:

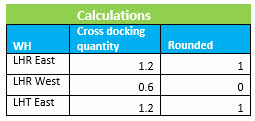

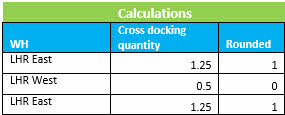

This is how the application has done the calculation and distributed the quantities:

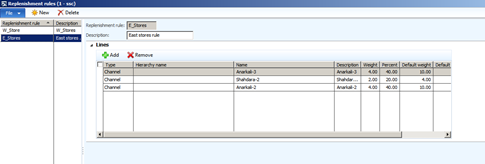

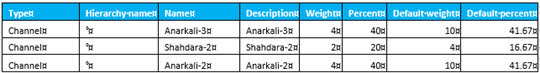

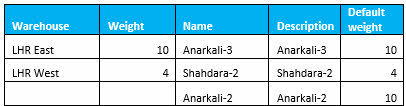

Replenishment rule created (E_Stores)

Replenishment rule created (E_Stores)

This is how the formula that the system has used to calculate the quantity in the code for the above cross docking data:

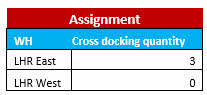

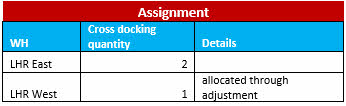

And finally the application assigns the following to each individual warehouse:

The application checks the remaining Cross docking quantity of. 1 and then allocates the remaining quantity to the same Cross docking line, i.e. WH = LHR East. So the WH LHR East gets 3 as its cross docking quantity in total rather than 2.

Location weight

On the same Planned cross docking form, clear the calculations from previous steps using the Clear quantities button on the action pane strip. Now select Location weight as the distribution method and calculate the quantities. Use this method when you want to allocate the quantity to stores based on warehouse default weight.

This is how the application has done the calculation and distributed the quantities:

This is how system has calculated the quantity in the code for above cross docking data. The formula used is:

And finally the application assigns the following to each individual warehouse:

Fixed quantity for all

Now select the third distribution method on the Planned cross docking form. Use this method when you need to allocate a fixed quantity of inventory to the warehouses. In this case, the calculation formula becomes:

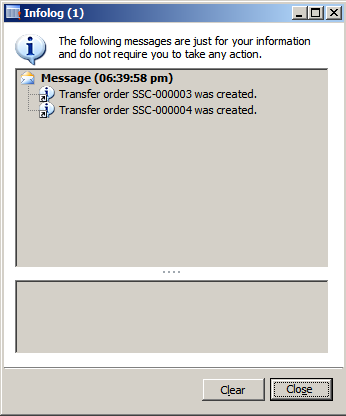

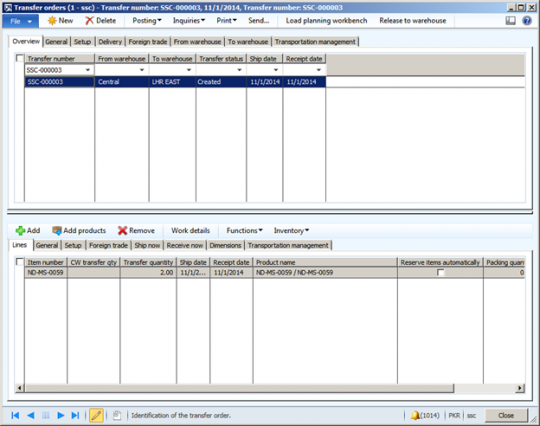

Let's proceed and create transfer orders from the Planned cross docking form. Click the ‘Create order' button and it will create the transfer orders as shown below.

We can look at each of the transfer order from:

Inventory management>Periodic>Transfer orders form.

Process the transfer order as you normally do.

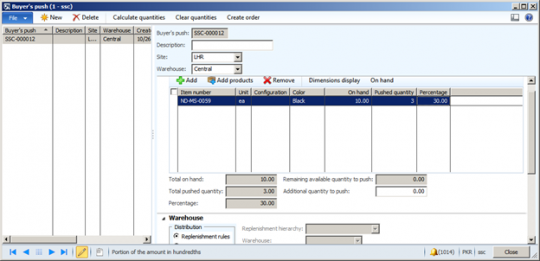

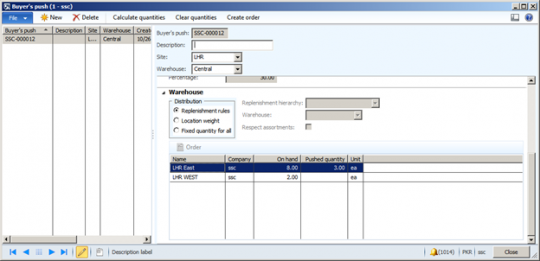

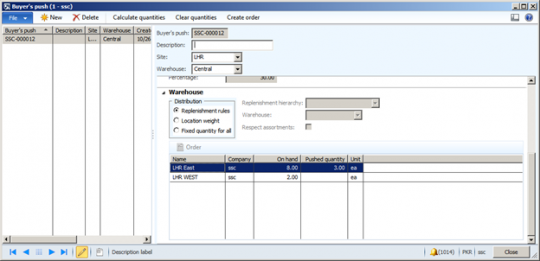

Buyer's Push

This process of replenishment is quite similar to cross docking, except that it works on item on-hand quantity rather than purchase order quantity as the process does not initiate from a purchase order. The idea is to push the on-hand quantity available in a warehouse to other warehouses (retail channels) using distribution methods. The three distribution methods i.e. Replenishment rules, Location weight, and "Fixed quantity for all" also work with buyer's push. However, in order to find the replenishment rule for the distribution, buyer's push does not look for the service category associated with the vendor. Rather,  it looks at the retail product category to get the replenishment rule. The rest of the quantity calculation and formulas are similar to what we have seen for cross docking.

it looks at the retail product category to get the replenishment rule. The rest of the quantity calculation and formulas are similar to what we have seen for cross docking.

it looks at the retail product category to get the replenishment rule. The rest of the quantity calculation and formulas are similar to what we have seen for cross docking.

it looks at the retail product category to get the replenishment rule. The rest of the quantity calculation and formulas are similar to what we have seen for cross docking.

I hope you find this article helpful. If you have any questions about Retail replenishment, please feel free to contact me.

Comments

Post a Comment