Overview: How inbound loads are created, registered, and received

Warehouse handling of inbound loads for purchase orders

This topic describes the warehouse handling process for inbound loads for purchase orders.

For each inbound load, your system should already include a related sales order, and it might also contain a related load specification and/or transportation plan. For more information about how to create and manage inbound loads, see Business process: Planning transportation for inbound loads.

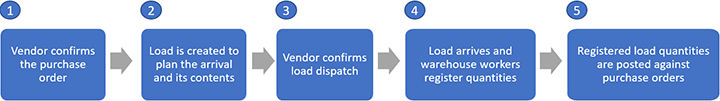

Overview: How inbound loads are created, registered, and received

The following illustration shows the typical flow for handling inbound loads that have purchase order quantities when they arrive at your warehouse.

The vendor confirms the purchase order.

The process begins when a purchase order is entered into the system and then delivered to a vendor, who confirms the order. The purchase order must exist before you can create an inbound load record. However, you can create the inbound load even if the order hasn't been confirmed. For more information, see Approve and confirm purchase orders.

An inbound load record is created to plan the arrival and its contents.

The inbound load record represents a vendor shipment of one or more purchase orders. The load is expected to arrive at the warehouse as one physical transportation unit (such as a truckload). The inbound load record is used for planning purposes and lets the logistics coordinator track the load's progress from the vendor. It's also used to register order line quantities and manage progress through warehouse operations, such as arrival and put-away work. Loads can be created either automatically or manually, and they can be based on either a purchase order or an advanced shipment notice (ASN) from the vendor. For more information, see Create or modify an inbound load.

The vendor confirms load dispatch.

When the vendor dispatches the load, the logistics coordinator at the receiving warehouse confirms the load shipment. If the receiving company is using the Transportation management module, inbound shipment confirmation will trigger other load management processes that are associated with the inbound loads. For more information, see Confirm a load for shipping.

The load arrives at the warehouse, and workers register quantities.

When a truckload arrives at the warehouse receiving dock, warehouse workers register the load quantities. When the Warehouse management module is used, workers do the registration by using mobile devices. For more information, see Product receipt against purchase orders - registration and the Register item quantities that arrive on an inbound load section.

Registered load quantities are posted against purchase orders.

After the load quantities have been registered as arrived, those quantities must be product receipt–posted to the company's inventory ledger to record the physical stock increase. For more information, see Product receipt against purchase orders - product receipt and Post registered product quantities against purchase orders.

Register item quantities that arrive on an inbound load

Microsoft Dynamics 365 Supply Chain Management supports several operational approaches to recording the arrival of ordered products. Therefore, you can configure the system to match your specific business requirements. This section describes how to register incoming item quantities by using a mobile device when advanced warehouse management is turned on in the system. However, there is an alternative flow that is based on using the item arrival journal instead of a mobile device. For more information about that flow, see Register items for an advanced warehousing enabled item using an item arrival journal.

When an inbound load first arrives at the warehouse, warehouse workers must register the item quantities that are included in the shipment. Typically, they use handheld scanners. This workflow is available only if the following items are present in the system:

An inbound load record that describes the item quantities that are expected in the shipment

Typically, the vendor confirms the inbound load record before the shipment arrives at the warehouse. Therefore, the load has a status of Shipped. However, warehouse workers can also register items quantities for loads that have a status of Open or Received.

A mobile device menu that is configured to support load receiving

The warehouse app for mobile devices supports the following work creation processes:

- Load item receiving

- Load item receiving and put away

- Mixed license plate receiving, where the Source document line identification method field for the mobile device menu item is set to Load item receiving. For more information, see Mixed license plate receiving.

- Mixed license plate receiving and put away, where the Source document line identification method field for the mobile device menu item is set to Load item receiving. For more information, see Mixed license plate receiving.

Note

Regardless of the process, the system will generate work to take quantities that are registered in the receiving location and put them away in the regular storage location. When the Load item receiving and put away or Mixed license plate receiving and put-away process is used, the worker who registered the load quantity will also be instructed by the device to do the put-away work as part of the registration task. By contrast, for the Load item receiving and Mixed license plate receiving processes, the assumption is that put-away work will be done separately from the registration task.

A work template that defines pick and put work for incoming loads

This item is related to the previous items. You must have at least one work template for the Purchase order work order type, and it must contain a set of pick/put work types.

The mobile device guides the warehouse receiving clerk through the flow for load quantity registration. At a minimum, this flow includes the following steps for each load ID:

- Enter the load ID.

- Enter the item number for a received item.

- Enter the quantity of that item number that is received.

- Enter the license plate number for the item's initial location, if the system isn't set up to generate this number automatically.

- Tap OK.

After the worker completes these steps, the system makes the following updates on the appropriate entities, provided that the purchase order line quantity arrived on one load and all load quantities have been registered:

Note that warehouse workers can register the receipt of a purchase order with one or more associated loads without using the Load item receiving process. The following methods are available:

- On the mobile device: Use the Purchase order line receiving and Purchase order line receiving and put away processes. (If more than one load exists for the purchase order line quantity, the worker can't use the Purchase order line receiving process. Instead, the worker will be instructed to use the device action that is associated with the Load item receiving process.)

- On the client: Use the item arrival journal.

- On the client: Use the Registration action that can be accessed from the purchase order line.

Comments

Post a Comment